Issue Type | Phenomenon Description | Core Causes | Solutions |

Standard Curve No Gradient/Poor Linearity | No obvious concentration dependence of standard OD values, R²<0.98 | 1. Standard degradation or dilution error;

2. Unsuitable coating buffer pH (deviating from antigen isoelectric point);

3. Uncontrolled incubation temperature/time;

4. Insufficient substrate reaction | 1. Aliquot and store standards, avoid repeated freeze-thaw, perform serial dilution strictly;

2. Adjust coating buffer pH (0.05M carbonate buffer, pH9.6 recommended);

3. Coat at 4℃ overnight, incubate standards at 37℃ for 1–2h;

4. React substrate at room temperature in dark for 15–30min, terminate reaction timely |

High Blank Well OD Value | OD value of blank wells (no antigen/antibody) significantly exceeds normal threshold | 1. Excessive enzyme-labeled secondary antibody concentration or non-specific binding;

2. Inadequate blocking (improper buffer or short time);

3. Incomplete washing with residual enzyme-labeled reagent;

4. Substrate self-coloration or contamination | 1. Reduce secondary antibody concentration, use cross-adsorbed secondary antibody;

2. Block with 5% non-fat milk or BSA for 1–2h at room temperature;

3. Wash plate 5–6 times with wash buffer containing 0.05% Tween-20, 30s each time;

4. Use fresh substrate and avoid reagent contamination |

Low/No Sample OD Signal | Sample OD value close to blank, below detection limit | 1. Low antigen/antibody concentration or inactivation;

2. Poor coating efficiency (antigen not adsorbed on plate);

3. Insufficient incubation time or low temperature;

4. Substrate inactivation or premature termination | 1. Optimize antigen/antibody concentration and verify reagent validity;

2. Increase coated antigen dosage, coat at 4℃ overnight;

3. Incubate samples at 37℃ for 2h or 4℃ overnight;

4. Use valid substrate and strictly control reaction time |

Poor Reproducibility (High Inter-well/Inter-plate Variation) | Coefficient of variation (CV) of OD values for same-concentration samples >10% | 1. Uneven sample loading volume;

2. Residual liquid difference between wells after washing;

3. Uneven heating of microplate during incubation;

4. Disordered substrate addition sequence | 1. Use multi-channel pipette and tap gently to mix after loading;

2. Invert and pat dry plate after washing to avoid residual liquid at well bottom;

3. Seal microplate during incubation and place in constant temperature incubator;

4. Add substrate rapidly in the same sequence |

Hook Effect (Low OD Value for High-concentration Samples) | OD value of high-concentration antigen samples lower than that of medium-concentration samples | Excessively high antigen concentration leads to separate binding of antigen to solid-phase antibody and enzyme-labeled antibody, failing to form sandwich complex | 1. Perform gradient dilution on high-concentration samples before detection;

2. Reduce coated antibody concentration and optimize reaction system ratio;

3. Shorten incubation time between antigen and antibody |

Non-specific Coloration (High Background) | Uniform coloration of whole plate, small difference between sample wells and blank wells | 1. Non-specific antibody binding;

2. Cross-reaction between blocking buffer and antigen;

3. Low wash buffer concentration;

4. Insufficient humidity during incubation, leading to edge well drying | 1. Optimize the antibody;

2.Replace blocking buffer (e.g., BSA instead of non-fat milk);

3. Increase Tween-20 concentration in wash buffer to 0.1%;

4. Add wet gauze in incubator to prevent edge effect |

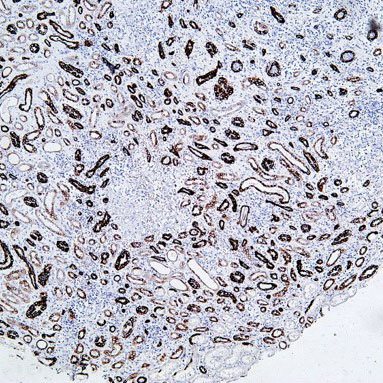

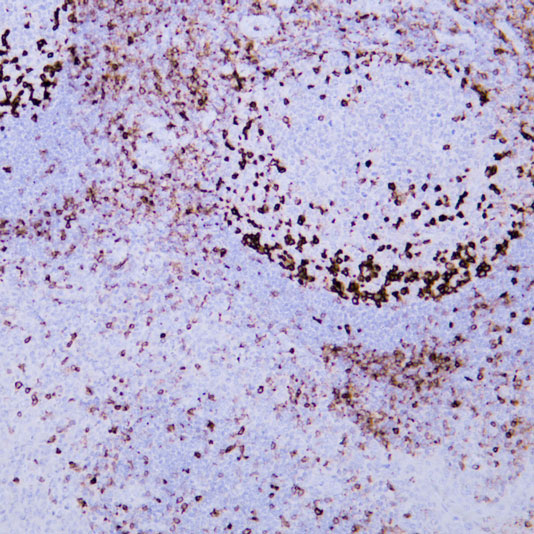

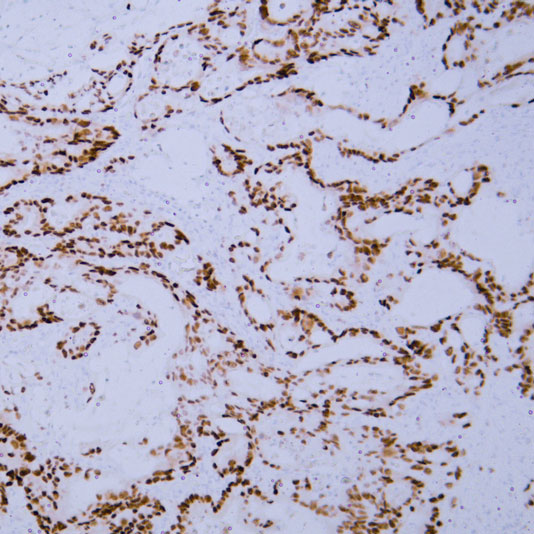

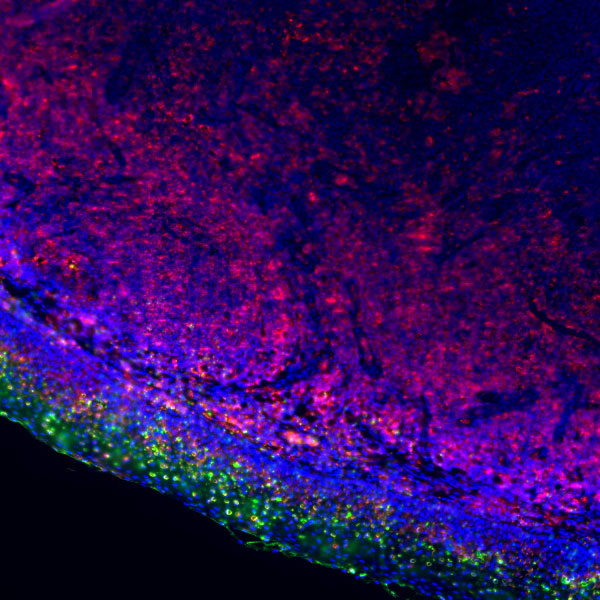

Related Promotional Journal Downloads

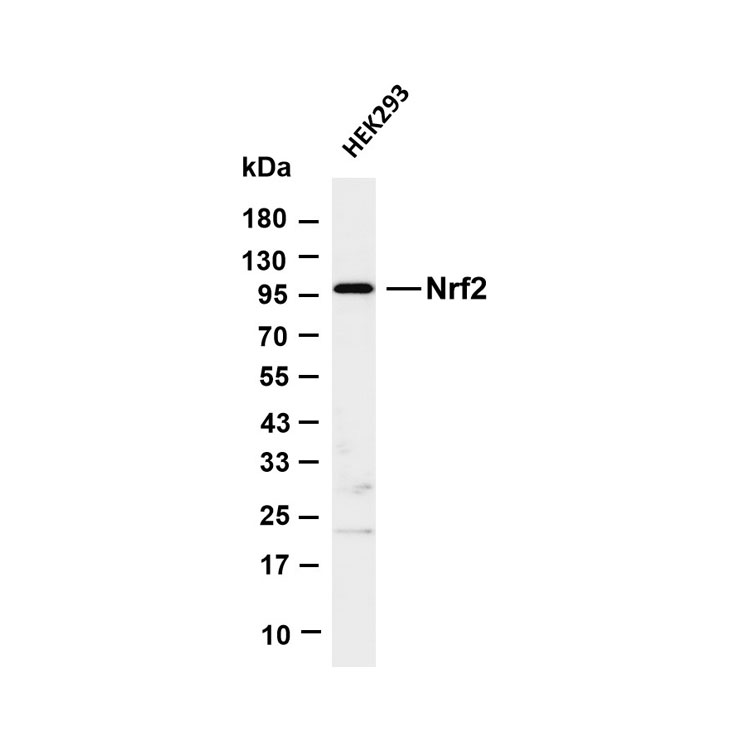

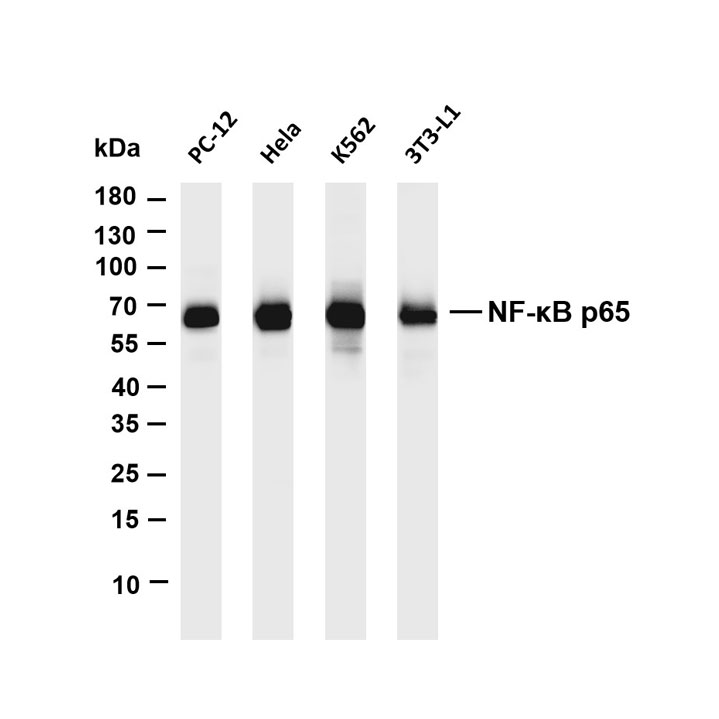

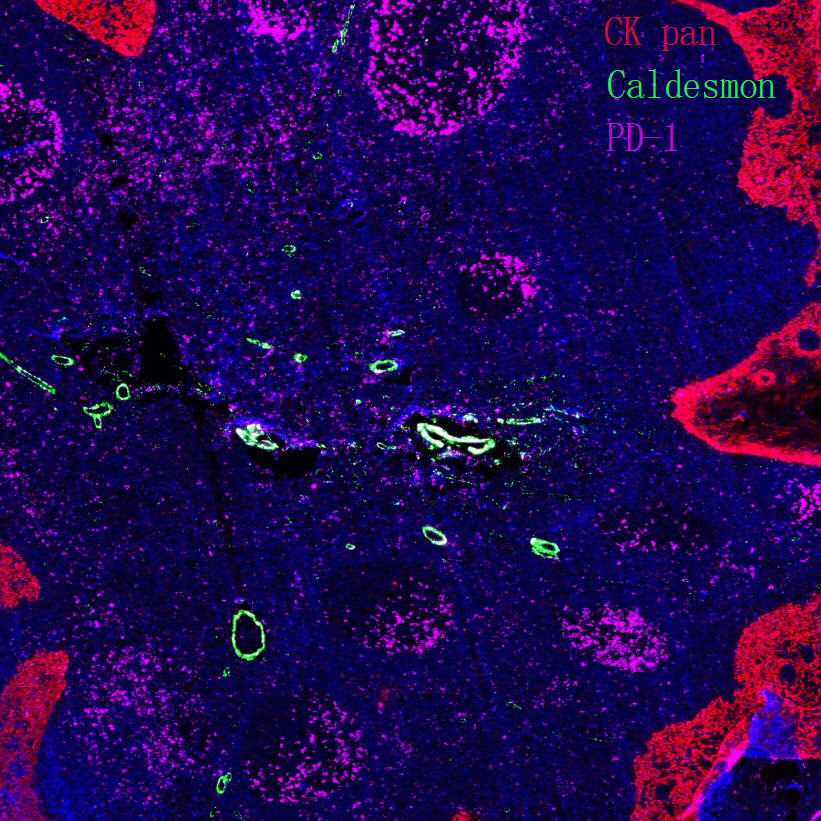

30,000+ high- quality products available online

Primary Antibodies, Secondary Antibodies, mIHC Kits, ELISA Kits, Proteins, Molecular Biology Products,Cell Lines,Reagents ...

Contact Us